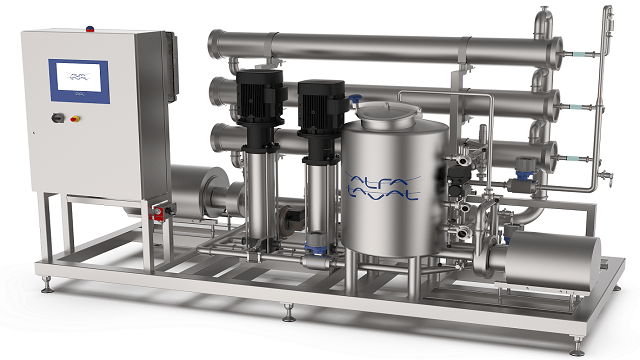

MultiSystem

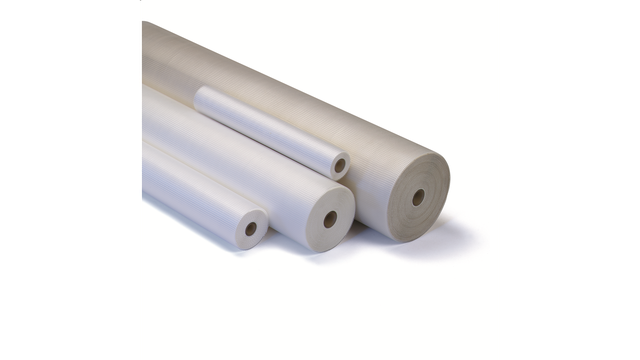

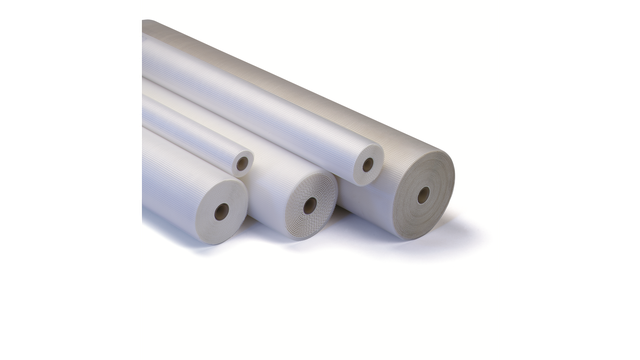

The self-contained and semi-automatic Alfa Laval MultiSystem in a sanitary design is a flexible and multipurpose membrane filtration system for food processing applications. It works with MF, UF, NF and RO cross-flow filtration processes and operates in both batch, semi-batch and continuous modes. This Alfa Laval membrane filter system fits the entire range of 8.0" spiral wound membranes available from Alfa Laval, including the high temperature and pH tolerant Alfa Laval pHt™ membranes.

Experience scalable Alfa Laval membrane filtration technology

- Product capacity from few 100 l/h up to 6 m³/h

- Flexible membrane areas from 65 m² to 240 m²

- Automatic PLC-based control of batch, semi-batch and continuous processes incl. data logging and easy data access by USB connection

- Ideal for food processing applications incl. recovery of condensates water and generating of purified RO quality water for diafiltration

- All membrane filtration equipment and main components, including unique high-performance spiral membranes, manufactured by Alfa Laval

Sanitary design with PLC-driven precision delivers exceptional performance in food applications

Looking for a compact, flexible membrane filtration system to optimize small-scale membrane filtration and ensure smooth scale-up to full production? The Alfa Laval MultiSystem delivers exceptional performance in food applications, combining a space-saving design with versatility and reliability to help accelerate innovation and maintain consistent quality.

From the purification of proteins, sugar and starch to the concentration of peptides and amino streams, recovery of water from condensates; or the generation of RO-quality water for diafiltration, Alfa Laval has installed more than 2,500 membrane filtration systems worldwide.

How do membrane filter systems work?

The sanitary Alfa Laval membrane filtration MultiSystem is a semi-automatic and fully integrated, skid-mounted membrane filtration system which can be easily connected to upstream and downstream unit operations in the process, minimizing installation time and cost.

The modular skid comes with all necessary sanitary components, such as pumps, housings, feed/CIP tank, valves, heat exchangers, transmitters, fittings and a control panel. Our membrane filtration equipment complies with major global standards, including EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006, and FDA regulations (CFR Title 21) for safe and reliable processing.

The PLC-based control system secures automatic control of production sequences including flow, VCF (Volumetric Concentration Factor), temperature, tank level, pressure and diafiltration volume or ratio control for high process stability, reproducibility and precise performance evaluation.

Internal data logging is easily extractable via USB.

Options

The basic Alfa Laval MultiSystem is further available with the optional membrane filtration equipment:

- One extra housing to increase the spiral membrane area by 50%

- Online monitoring and data collection

- Remote monitoring and control (VNC) and collection via direct connection on Profinet or Modem connections (secured VPN)

Which types of membranes are used in membrane filtration systems?

The Alfa Laval MultiSystem is engineered for maximum flexibility, supporting the complete range of 8.0” spiral membranes from Alfa Laval. Test MF, UF, NF and RO processes in batch, semi-batch, or continuous operation, with integrated diafiltration capabilities.

How can we help you?

Submit a form and let’s discuss which membrane filter system can help you achieve top quality products that comply with the many stringent requirements from both consumers and public authorities.