SB anti-vakuumventil

Integrated in a SCANDI BREW® tank top system, the Alfa Laval SB Anti Vacuum Valve is a compact safety valve that minimizes the risk of implosion of tanks when a vacuum condition arises. These conditions occur while filling or emptying the vessel of liquid, cool rinsing after hot-cleaning or caustic cleaning in a CO2 atmosphere. Designed for use in the brewery, dairy, food and beverage industries, it helps optimize the safety, reliability and performance of critical processes and maximize uptime.

Low initial cost of investment

With a durable and robust design, the SB Anti Vacuum Valve protects tanks from collapse due to internal vacuum conditions. Its low initial cost of investment provides return on investment over the long term as a result of operational reliability and enhanced service life, combined with reduced product loss, greater process safety and improved hygiene.

Compact valve design

Compact and robust, the hygienic SB Anti Vacuum Valve easily fits onto the top of any closed tank. The valve size and setting is based on the tank vacuum rating, maximum allowable emptying speed, cleaning procedure and process requirements.

Superior valve hygiene

Engineered to provide excellent hygiene and cleanability, the SB Anti Vacuum Valve features high-quality stainless steel with a surface finish of Ra ≤ 0.8μm. Alfa Laval seal technology also offers greater thermal stability, better chemical resistance and improved tensile strength. This highly reliable valve conforms to PED 97/23/EC requirements. Alfa Laval3.1 traceability certification is also available upon request.

Product benefits

- Low initial cost of investment

- Compact design

- Superior hygiene

- Easy installation

Produktkatalog

Så fungerar det

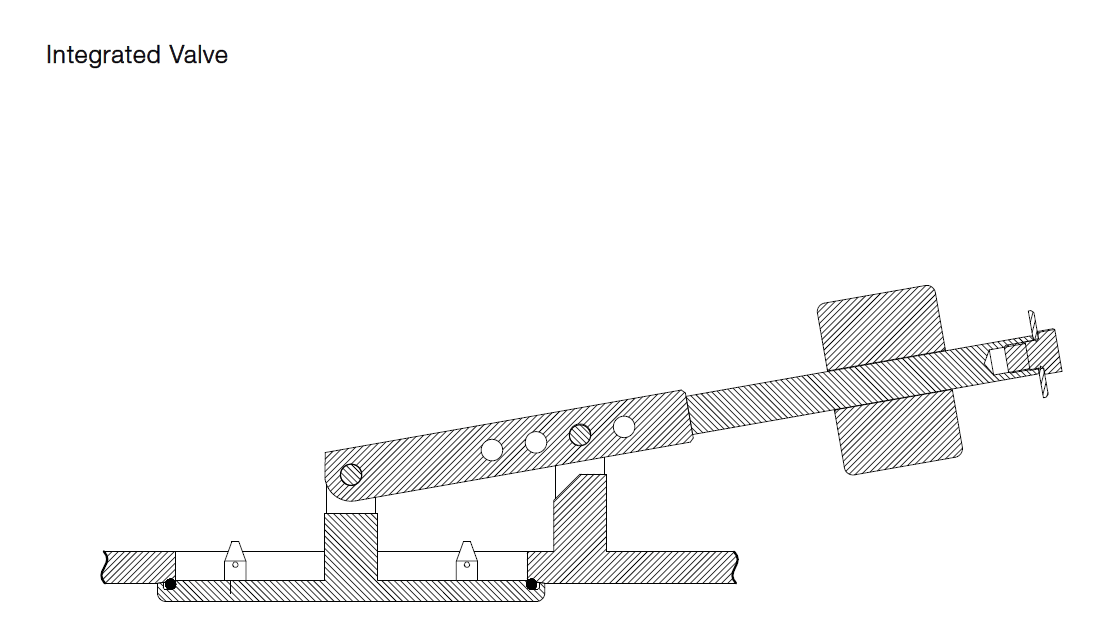

Construction

The Alfa Laval SB Anti Vacuum Valve is a flange mounted safety valve that an integral part of a SCANDI BREW® tank top system. All product wetted steel parts are made of AISI 316L stainless steel with a surface roughness of Ra<0.8 μm; all other steel parts are made of AISI 304L stainless steel. All product wetted seals are made of EPDM and all product wetted polymers are made of PEEK.

It is available in two versions:

- Integrated in a SCANDI BREW® tank top system

- Mounted on its own counter flange

The valve should be seated horizontally. A maximum inclination of 10° is acceptable, but the lever arm must then point in to the center of the cylindroconical tank top.

Operating principle

The SB Anti Vacuum Valve is delivered with counterweight set and locked for an individual opening vacuum to suit the tank design data. When a vacuum in the tank is lower than the preset opening value, the valve opens and lets in atmospheric air.

Cleaning-in-Place (CIP)

The Anti Vacuum Valve is cleaned, when closed, by the tank cleaning head. However, this does not include cleaning of the valve seat. There are two options available for CIP of the valve seat (see Options below).

It is very important to note that if the cleaning procedure includes hot cleaning, the valve should be dimensioned with the purpose of preventing implosion from the vacuum that appears when flushing with cold water.

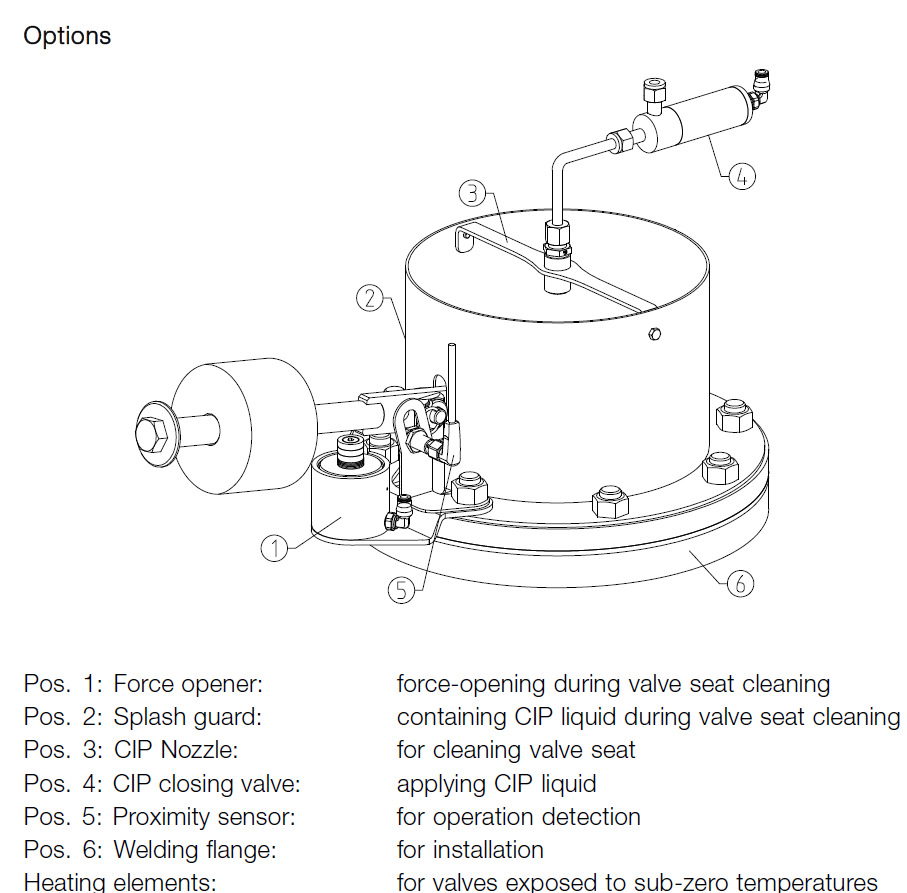

Options

These two options are available for Cleaning-In-Place (CIP) of the valve seat.

CIP Kit 1: Force opener and splash guard

The valve is forced opened during tank CIP. The cleaning of valve seat is dependent on cleaning jets from the tank cleaning head. Any CIP liquid that escapes the tank is contained by the splash guard and drains back into the tank.

CIP Kit 2: Force opener, splash guard, CIP nozzle and CIP closing valve

The valve is forced opened during tank CIP. The cleaning of valve seat is performed by the CIP nozzle. All CIP liquid from the CIP nozzle is contained by the splash guard and drains back into the tank.