Clariot

Clariot är en lösning för tillståndsövervakning, konstruerad för att hantera de unika och komplexa utmaningar som hygienisk processutrustning står inför. Clariots avancerade sensorer är skräddarsydda för pumpar, omrörare och annan roterande utrustning, och ger unik översikt över maskinernas skick. Clariot har utvecklats för att leverera precision och med mer än 140 års expertis som utgångspunkt ger det företag snabba insikter och rekommendationer.

En lösning. Lätt att installera. Enkel att skala upp

- Dygnet runt-övervakning garanterar ständig överblick

- Lättinstallerad lösning som gör att du är igång på bara några minuter

- Branschledande analysapplikation ger en sömlös användarupplevelse

- Färre driftstopp ger bättre säkerhetsåtgärder på fabriksgolvet

- Snabba aviseringar upptäcker problem i tidigt skede för att förlänga tillgångens livslängd

Clariots tillståndsövervakningssystem kombinerar oöverträffad insyn i din utrustnings hälsa och över ett sekel av kunskap om hygieniska processer för att bygga branschens ledande lösning för prediktivt underhåll.

Clariot installeras på bara några minuter och går bortom vibrationsdata för att ge ditt team användbara insikter och teknik för uppskalning på flera anläggningar.

Varje droppe räknas

För industrier som förser samhället med rent vatten, livsmedel och läkemedel är Clariot den intelligenta underhållslösningen som upptäcker problem tidigt för att maximera prestanda och minimera driftstopp.

Förbättra drifteffektiviteten

Maximera effektivitet och lönsamhet genom att eliminera slöseri med tid och produkter

Hållbarhet utan kompromisser

Minska ditt koldioxidavtryck, spara resurser och förläng tillgångarnas livslängd

Tilltro till varje beslut

Förlita dig på branschspecifika data för mer exakt analys och hjälp

Smidig, smart, enkel att använda

Slipp gissningar med användbara insikter och ett intuitivt gränssnitt

Hur fungerar Clariot-tillståndsövervakningen

Clariot är ett vibrationssystem för tillståndsövervakning som utformats för hygienisk processutrustning. Det är kompatibelt med pumpar, omrörare och annan roterande utrustning. Clariot bygger på över ett sekel av branschkunskap, så det är enkelt att installera och förstår din verksamhet.

Enkel installation, smartare insikter

Övervaka

Sensorer som är uppkopplade via IoT arbetar dygnet runt och samlar in vibrationsdata för att ge tydlig och detaljerad information om hur utrustningen mår

Analysera

AI-baserad analys upptäcker och identifierar bakomliggande orsaker till maskinfel relaterade till process-, installations- och mekaniska förhållanden innan haverier uppstår

Agera

Noteringar med steg-för-steg-instruktioner eliminerar gissningar och gör det möjligt för medlemmar att vidta omedelbara åtgärder

Expandera

Alfa Lavals globala närvaro och lösning gör implementeringen i hela företaget sömlös, vilket möjliggör förbättrad effektivitet på olika siter

Köpguide

Kom igång med Clariot och ladda ner köpguiden för tillståndsövervakning. Identifiera och välj rätt lösning för tillståndsövervakning för dina behov och börja utnyttja fördelarna med prediktiv optimering.

Gå från installation till insikt på nolltid

Clariot VX™-sensor

Den IoT-anslutna Clariot VX-sensorn (tidigare CM) installeras på bara några minuter och övervakar vibrationer, enhetstemperaturer och körtid för att ge kontinuerlig övervakning dygnet runt.

Clariot Connect™-gateway

Den säkra gatewayen Clariot Connect (tidigare CM Connect) och instrumentpanelen ger unik insyn i maskinernas skick – var du än befinner dig – så att du kan vidta åtgärder för att undvika störningar.

Clariot™-analys

Förvandla insikter till drifttid med Clariots analyser. Clariot är utformat för hygieniska processer och ger exakta rekommendationer som eliminerar behovet av utredningar

Förutspå. Förhindra. Utföra.

Med förebyggande underhåll dygnet runt upptäcker Clariots tillståndsbaserade övervakningssystem problem i tidigt skede, hjälper din utrustning att hålla längre och sparar resurser.

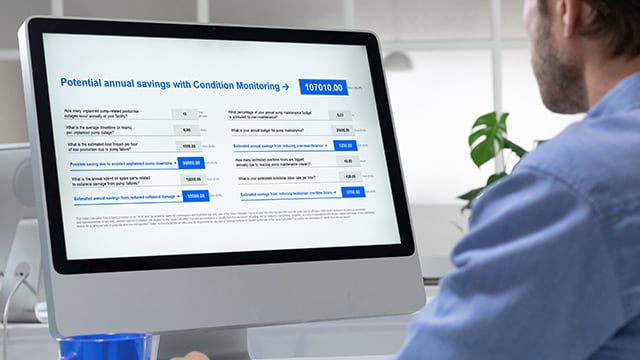

Ange dina oplanerade produktionsstopp för att upptäcka dina potentiella besparingar.

Nöjda kunder

Animationer

Besök animationssidan för att få se insidan av en produkt och förstå hur den fungerar.

Prenumerera på nyhetsbrevet "near"

Håll dig uppdaterad om viktiga hållbarhetsfrågor och möjligheter inom din bransch och dina processer!