Edible oil refining process systems

Refining crude oil into high-quality edible oil begins with control of every stage, from degumming, neutralization and dewaxing to bleaching and deodorization to reduce GE and 3-MCPD. Each step in the edible oil manufacturing process is to enhance purity, safety, taste and appearance. With Alfa Laval’s advanced edible oil refining process solutions, you can optimize your entire edible oil production line, deliver consistent quality, reduce operating costs, and keep pace with growing a demand.

Versatile, highly reliable, easy-to-operate systems for quality edible oils

- Broad range of robust, reliable and easy-to-operate components, equipment and systems

- Expertise to integrate edible oil processing equipment into custom applications

- Vast experience in edible oil refining system design, installation, commissioning, and service and support

- High product quality and yield with minimal losses and reduced utility usage

Alfa Laval is fully responsible, and I don't have to worry about a thing." - Henk Vedder, Maintenance Manager, Cargill, Amsterdam.

Alfa Laval experts really know what to do, how to repair things and how to deal with the problems. We insist on always going back to Alfa Laval for after-sales service. - Haji Matan Ibrahim, Mill Manager/Chief Engineer of Kilang Sawit Bukit Bandi.

We get regular support from Alfa Laval team. We are happy with the Alfa Laval team.” - Ramhari Gaikwad, technical manager, Shalimar Nutrients.

Our edible oil production line portfolio

After oil clarification (for pressed oils), the oil can be refined as shown below.

After pressing and clarification, crude oil passes through a series of edible oil refining processes – each optimized to preserve product integrity and flavour:

- Degumming (water or physical refining for gum removal)

- Neutralization (chemical refining for free fatty acid removal)

- Dewaxing (cold stability)

- Bleaching (pigment and impurity removal)

- Deodorization under vacuum and steam (3‑MCPD and GE reduction)

Detailed stages of the edible oil refining process

The crude oil is transferred either to special degumming in the physical refining process, to water degumming, or directly to neutralization in the chemical refining process. In chemical refining, free fatty acids undergo a reaction to form aqueous soap, which is removed from the oil using centrifuges.

The physical edible oil refining process removes certain impurities – mainly phosphatides (phospholipids or gums) from the oil. Some oils, such as sunflower and corn oils, pass through a dewaxing step to achieve the prescribed cold stability to retain clarity at low temperatures.

Next, the bleaching process eliminates impurities, such as metals, soap residues and colour components. Finally, deodorization extends shelf life by breaking down residual colour, peroxides, or off-flavour compounds .

Volatile compounds, mostly fatty acids, are removed through steam stripping at 240° – 260°C under vacuum. This stage also produces fatty acid distillates, a valuable by-product of physical refining, though less common in chemical refining.

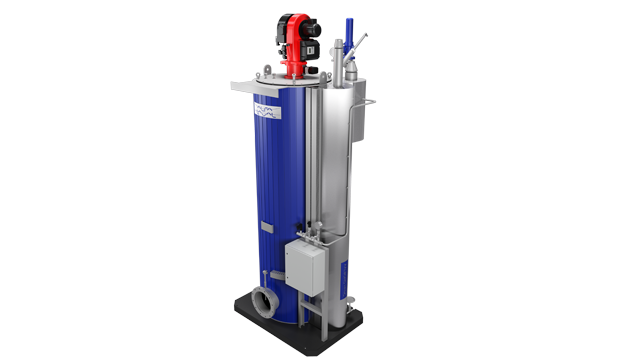

To cut operating costs further, Alfa Laval’s utility process systems help reduce your costs for power, water, steam, fuel, and cooling media across your edible oil refinery.

Optimize your edible oil production line

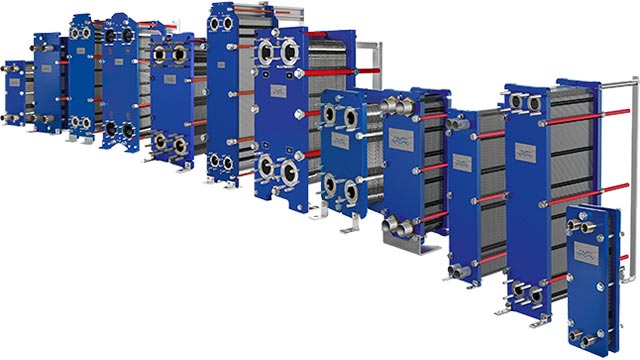

Maximize yield, quality, and safety with Alfa Laval’s edible oil refining solutions. With over 3,700 Alfa Laval patents – including more than 140 dedicated to edible oil systems, we optimize every stage of the refining process. Continuous R&D investment ensures our equipment evolves with innovative technology to boost performance, reduce losses, and improve efficiency.

Whether installing a complete edible oil refining system or upgrading individual components, Alfa Laval delivers solutions tailored to your needs. Expect optimal design, easy installation, intuitive operation, reliable performance, and minimal product loss. By combining global expertise with local service, you gain higher efficiency, lower life-cycle costs, and stronger returns for your business.

Onze klanten:

References

- More than 500 refineries (with neutralization/degumming, bleaching, deodorization)

- More than 140 dewaxing plants

- More than 75 dry fractionation plants

- More than 50 hydrogenation plants

- More than 30 interesterification plants

Publications

See an extensive list of peer-reviewed publications by Alfa Laval's experienced experts.

Our expert says

Core Alfa Laval edible oil refinery equipment:

Webinar voor de sector eetbare oliën

Onze deskundigen delen hun knowhow om het raffinageproces voor spijsolie te optimaliseren en onzuiverheden en vluchtige bestanddelen te verwijderen voor een betere productkwaliteit, veiligheid en opbrengst.