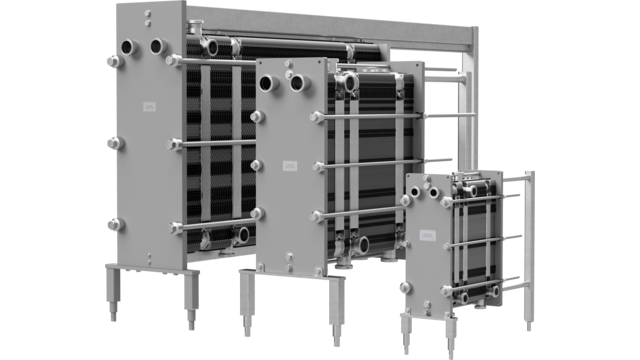

Hygienic WideGap

Increase your process hygiene and energy efficiency with our hygienic WideGap plate heat exchanger, part of Alfa Laval Hygienic line. Engineered specifically for fluids containing fibres and particles, this innovative technology enables impressive energy savings and heat recovery, surpassing the limitations of traditional shell and tube heat exchangers. Designed for food processing applications, the hygienic WideGap is perfect for a wide range of products, ranging from pulp-filled juices and purées to crushed tomatoes, dressings, and even plant-based beverages.

Heat recovery

Heat recovery is crucial for improving energy efficiency and reducing costs. The innovative plate pattern of the WideGap plate heat exchanger enables high heat recovery, even with high fibrous fluids. By running the plate heat exchanger product to product, heat transfer between fluids is optimized, resulting in efficient heat recovery. This process achieves a close temperature approach, enhancing heat transfer efficiency. By capturing and utilizing heat from the outgoing fluid to preheat the incoming fluid, significant energy savings can be achieved.

Våra kunder

Service

Ökad drifttid för hygieniska plattvärmeväxlare för livsmedel, mejeri och drycker

Öka produktiviteten och avkastningen på dina bearbetningslinjer med Alfa Lavals tjänster för dina hygieniska plattvärmeväxlare. Maximera avkastningen på din investering genom att hålla dem i gott skick. Rätt underhåll förlänger utrustningens livslängd och ger dig sinnesfrid.

Få enkel tillgång till reservdelar, servicekit, rutinmässigt eller förebyggande underhåll och hjälp med felsökning var du än befinner dig. Eller utnyttja avancerad service som rekonditionering av plattorna, integritetstestning eller visuell tillståndsbedömning av skicket. Eller ännu bättre, inta ett mer proaktivt förhållningssätt till säkerhet och drifttid med ett serviceavtal. Läs mer.

Så fungerar det

The versatile hygienic WideGap plate heat exchanger for fluids with large fibres and particles can be designed for various applications. The unit can be configured with asymmetrical channels allowing fluids carrying sizable particles to smoothly flow through the wide channel. By rearranging the plates into a symmetrical channel, heat recovery and substantial energy savings are enabled. Moreover, with its ingenious port design, fibres effortlessly navigate the channels without risk of clogging, enabling uninterrupted processing operations.

Branded features

SmoothPort

The streamlined SmoothPort™ prevents build-up and maximizes cleanability and drainability.

OpenChannel

OpenChannel™ allows longer operating time for fluids with particles and fibres.

Technology conversion: WideGap plate heat exchangers vs shell and tube

When considering heat exchangers for food processing, the WideGap plate heat exchangers offer a versatile and cost-efficient solution compared to the traditional shell and tube design.

- WideGap plate heat exchangers have a smaller footprint, saving valuable floor space. This also means transport and installation costs are lower.

- The design is versatile enabling the capacity to be adjusted simply by adding or removing plates, all within the existing frame.

- Maintenance is easier since all heat transfer surfaces are easily accessible for inspection or mechanical cleaning.

- A specially designed plate pattern ensures a high degree of turbulence over the whole plate, which not only reduces fouling but also makes cleaning very effective.

Hygienic line

This range of premium plate heat exchangers optimizes process hygiene and energy efficiency. They are specifically developed for hygienic applications thus raising the bar on hygiene overall while reducing the carbon footprint for food, beverage, pharmaceutical and other manufacturers who demand outstanding performance and total efficiency.