Carbon Capture Storage

Carbon capture, utilization, and storage (CCUS) is the process used to separate carbon dioxide emissions from industrial applications before transporting it to a long-term storage location. And, according to the International Energy Agency (IEA), global carbon capture capacity can reach up to 430 M tonnes CO₂ by 2030, more than sixfold increase from today.

Driving cost efficiency with cutting-edge CCUS solutions

- Maximizing heat recovery

- Reducing operational costs

- Reducing energy consumption

The biggest challenge in CCUS is cost. Carbon capture is an expensive process because energy use can account for up to 60% of a CCUS facility’s total operational costs.

With Alfa Laval’s heat exchanger technology, process optimization support, and thermal integration, you can maximize heat recovery and reduce energy consumption at the same time.

Our thermally efficient technologies can reduce energy consumption in amine-based, Hot Potassium Carbonate (HPC), Bioenergy Carbon Capture and Storage (BECCS) and Direct Air Capture (DACCS) plants by up to 40%.

Why our CCS technology is the solution

Alfa Laval plays a crucial role in the CCS value chain with technology both in and between every phase of the process. With trusted installations still operating efficiently at the oldest CCS facilities in the world, we have a broad range of products to help you:

- Optimize emitter processes to reduce your carbon emissions

- Reduce energy consumption during carbon capture

- Reduce your carbon footprint during transportation and storage.

- Optimize the utilization processes.

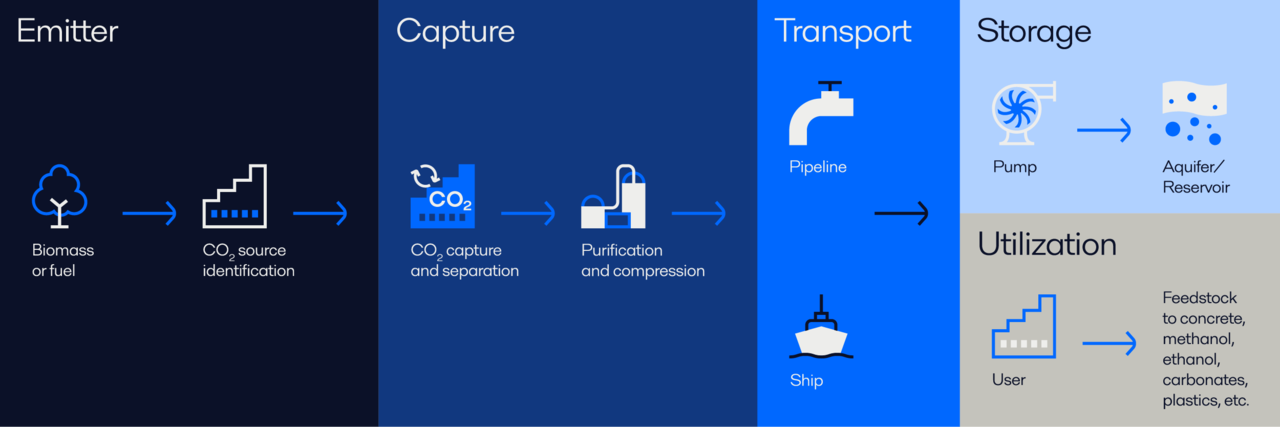

The CCUS value chain

CCUS Applications

CCUS Liquid absorption

- Flue gas heat recovery/ Steam generation

- Solvent cooling

- Lean/rich amine interchangers

- Stripper reboiler

CCUS Direct Air Capture (DAC)

In Direct Air Capture, the developing technology used to capture CO2 from the air is incredible energy intensive. Alfa Laval gasketed plate heat exchangers can reliably optimize the amount of energy consumed per tonne of carbon captured.

CCS eBook - Leveraging heat transfer in the carbon capture process

With the rapid development of carbon capture technologies, selecting the right system for your specific application is crucial. At Alfa Laval, we combine proven heat transfer expertise with innovative solutions to make carbon capture a more viable, scalable solution. Download our eBook to find solutions that fits your space constraints, water availability, energy consumption, and CAPEX.

Enabling e-methanol with CO2 utilization and advanced heat transfer technology

Combining renewable hydrogen with carbon capture paves the way for e-methanol. Alfa Laval offers a unique portfolio of state-of-the-art heat transfer technology to boost efficiency and reduce costs.

Accelerating cost-effective carbon capture

Alfa Laval heat exchanger technology has played a central part in over half of the world's CCS plants. Our Packinox plate-and-frame heat exchangers are facilitating the scale-up of carbon capture across the globe with our technology at the center of over half of the world's CCS plants.

- Direct contact cooler (DCC)

- Wash water cooler

- Absorption tower pump-around cooler

- Lean solvent cooler

- Lean/rich solvent interchanger

- Stripper reboiler

- Stripper condenser

- Compressor interstage cooler

- Flue gas heat recovery, conditioning, and steam generation

- Super critical CO2 cooler

Listen to Alfa Laval's CCUS experts

Gasketed plate heat exchangers - Boosting energy efficiency in CSS applications

The unique design of Alfa Laval’s compact gasketed plate heat exchangers make it possible for you to significantly improve solvent cooling in your CCS processes. All with less fouling, stress, and erosion on the internal plates.

But that is not all. With Alfa Laval as your CCS partner, you can reduce cooling water requirements by as much as 30%!

Watch the video to find out how you can boost energy efficiency in you CCS applications.

Welded heat exchanger technology slashing energy costs by up to 40%

If you use an Alfa Laval Compabloc plate heat exchanger as your stripper reboiler, you can utilize the steam generated from flue gas cooling.

In other words, with Alfa Laval you can reduce fresh steam requirements, fuel consumption, and emissions from your steam boiler. Bringing your total energy costs down by as much as 40%.

Saving over 70,000 tonnes of CO2 in cement production

With the ambition of becoming carbon neutral by 2050, Heidelberg materials are using Alfa Laval’s advanced CCS heat transfer technology to decarbonize their cement production.